“We run a custom fabrication business that encompasses two retail stores, one company workroom and up to four specialized outsourced factories. Before smartQ, we really had no way to track or organize our work orders. Jobs were constantly falling through the cracks due to misplaced work orders, and we were on the phones with each other non-stop and. Now, with smartQ, we enter each job along with images of the item, materials and a copy of the work order. As the job progresses, the workrooms are able to move the order along, and our retail stores can see the status of each job in real time. When there are questions or problems, the workroom uses smartQ to email questions and pictures to the salesperson. We are also able to track all customer communication, so everyone knows when and what has been communicated to the end consumer. There is no doubt that we save 10+ hours a week in communication and jobs don’t fall through the cracks anymore.

“We run a custom fabrication business that encompasses two retail stores, one company workroom and up to four specialized outsourced factories. Before smartQ, we really had no way to track or organize our work orders. Jobs were constantly falling through the cracks due to misplaced work orders, and we were on the phones with each other non-stop and. Now, with smartQ, we enter each job along with images of the item, materials and a copy of the work order. As the job progresses, the workrooms are able to move the order along, and our retail stores can see the status of each job in real time. When there are questions or problems, the workroom uses smartQ to email questions and pictures to the salesperson. We are also able to track all customer communication, so everyone knows when and what has been communicated to the end consumer. There is no doubt that we save 10+ hours a week in communication and jobs don’t fall through the cracks anymore.

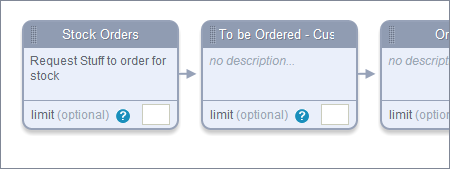

Customized workflow

We have also started using smartQ as a Kanban system for handling special orders and re-orders on stock items. This simplified system has allowed us to order inventory much more quickly as well as manage backorders and maintain proper control.

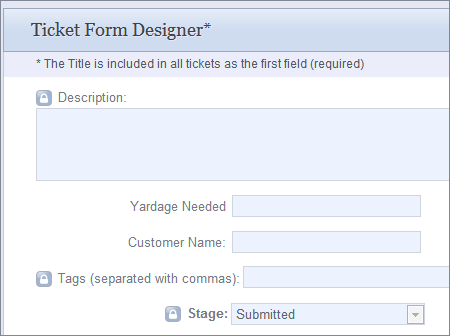

Customized ticket fields

The best part is we are able to do all of this for under $100/month, and we are able to give our outside vendors access and rights to the system very easily. Plus, since smartQ is so simple and intuitive, we have almost no training issues at all. The ROI we achieve from smartQ is incredible.”

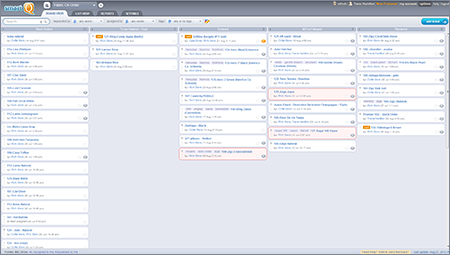

Tickets Board View

Travis Hamilton

Founder/CEO

U-Fab, Upholstery & Fabric Stores Inc.