Back in the 1940s, Toyota was struggling to develop a better system for their car production line. What they came up with is a production management system called Kanban.

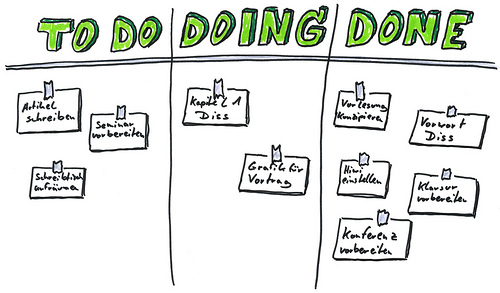

Kanban is basically a card board split into vertical columns – usually stages of a process. In the case of Toyota. the cards represented the car parts, and Kanban was used to make sure the parts are ordered in time and in correct numbers. But, as it turns out, the whole concept can be applied to any multi-step process management.

Today Kanban got a second life, rediscovered by software developers through Agile Software Development practices. Inspired by the “Pulling the Demand” principles of Kanban, they emerged with new “lean” ways to manage projects.

The most important principle of Kanban is limiting the work-in-progress (WIP)

By limiting the number of tickets per column, a Kanban board makes it so you can’t push more work down the pipeline to a team that is already saturated with tasks (hence the whole “new pull vs old push” terminology). It works particularly well for software when each feature takes a different amount of time to complete. It makes it difficult for managers to quantify the number of tasks that can be completed in advance, which results in an unrealistic number of tasks being pushed down the pipeline. Bad planning based on out-of-touch predictions often results in missed deadlines and an overloaded team.

The beauty of a Kanban board is that it represents a process visually and makes bottlenecks obvious. In many cases, it works better than a flat to-do list.

What works for car manufacturing and software development can also work for any process.

Kanban is simple, universal and adaptable. Any process of any complexity can be split into stages which can be represented on a Kanban board.

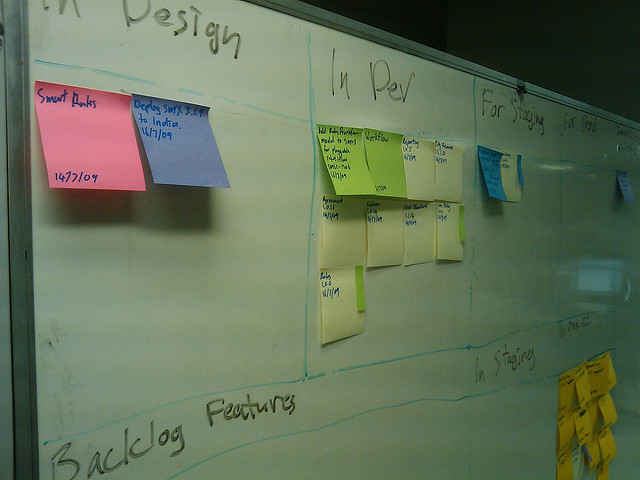

In fact, you can see it in one form or another in many meeting rooms: those infamous whiteboards with post-it notes.

For an extreme example, check how Delta used Kanban to merge two airlines in a giant project that lasted over 18 months.

Kanban is a good fit for: sales leads management, order tracking, support ticket system, issue management, and many more areas.

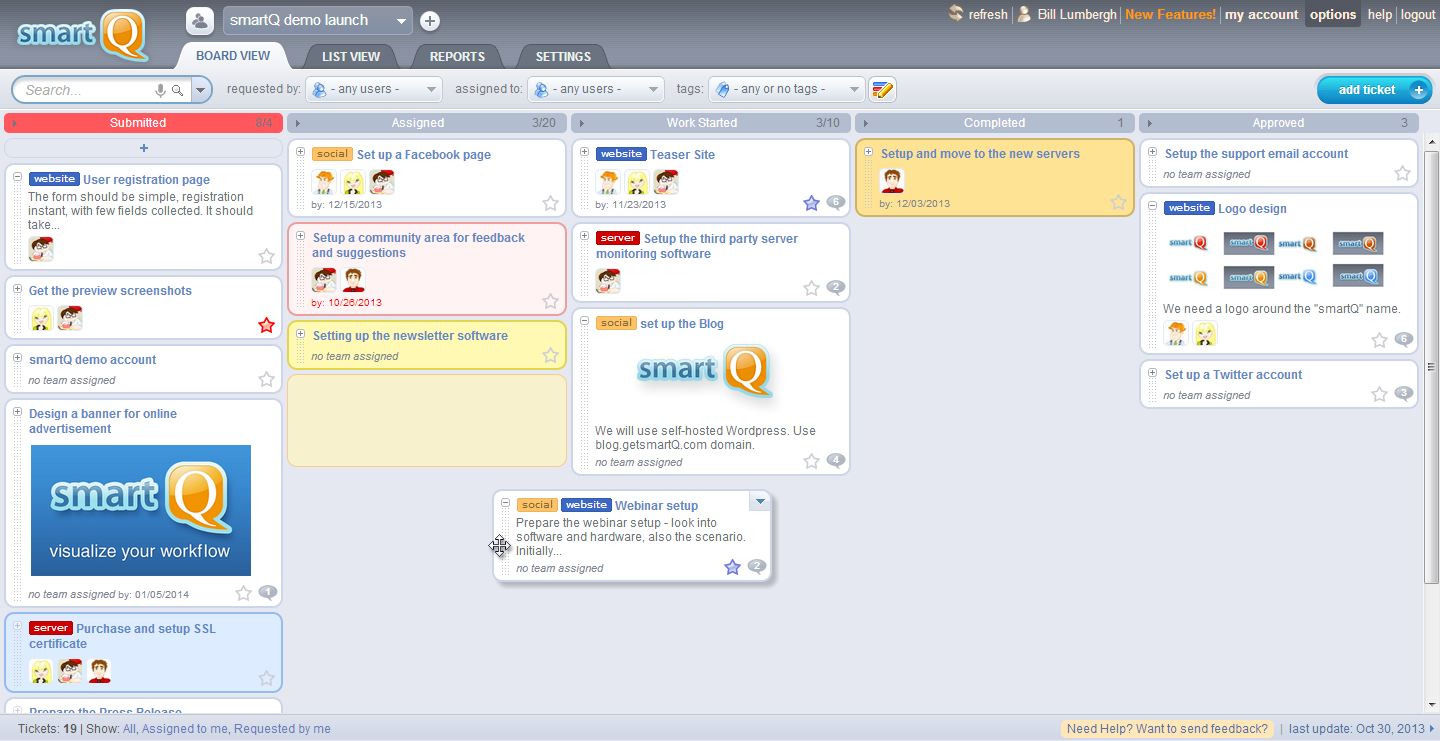

With multiple people working on the same project, often remotely, it is only natural that Kanban has moved online. A web-based Kanban board can be accessed from anywhere; the roles of who can do or see what can be restricted, the history of changes is logged, the search is easy and a wide range of reports and statistics can be generated. Not to mention that the tickets can be accompanied by files, pictures, links, etc.

With smartQ we tried to create an online Kanban tool that can be used by companies across a wide range of industries. It provides customizable workflows, adjustable team roles, and even custom ticket fields to collect a wide range of information. Check these examples:

Take a look around your organization – is there a process or project that can be organized as a Kanban?

Recommended literature on Kanban:

Also check online: